PRODUCT DEVELOPMENT

Input the idea and image to database and CAD system, and use 3D printer to repeat making the trial products.

Not only products but also catalogs, samples and point-of purchase display are developed and produced.

CASTING

The main material we use in our sand casting is bronze alloy. We are constantly working to enhance our processes to create beautiful products with smooth finishes, reduce failures, and guarantee timely delivery.

PROCESSING

Surface treatment, screw cutting and hole making for the foundry piece and brass-bar cutting.

Not only for our own products but also for others by contract.

For the various kinds of items and low-volume production, use NC/MC and Robot in our planned way.

POLISHING

Quality polishing is done at our own factory.

See the feature of each item and polish with own special way to raise the beauty and strength to reach the highest quality finish.

PLATING

Mainly, nickel chrome plating for water faucet parts and NPb treating for the surface of copper alloy.

95% of labor charge sales is not for our own products but for customer-supplied products.

Work also for gas and electronics parts as well as faucet parts.

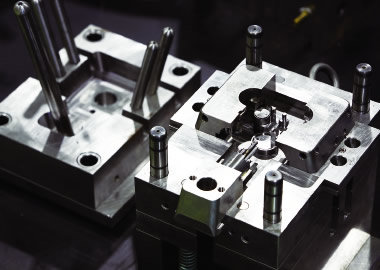

PLASTIC MOLD CASTING

With the most advanced machine, lay out and fabricate the mold for plastic products and parts which relate water.

The mold fabrication is not only for our own but also for OEM.

PLASTIC INJECTION MOLDING

Plastic forming for making both thick and thin parts with the equipment which makes the mold temperature up to 160℃ and keep the factory environment of no dust and no black spot.

ASSEMBLING/CHECKING

Each completed product is assembled by hands and inspected carefully through stern eyes.

The continuous improvement activity is to comply with the customers’ requirement for the quality, cost and delivery time as much as possible.